How to Use a Solar Dehydrator for Efficient Sun-Powered Food Drying

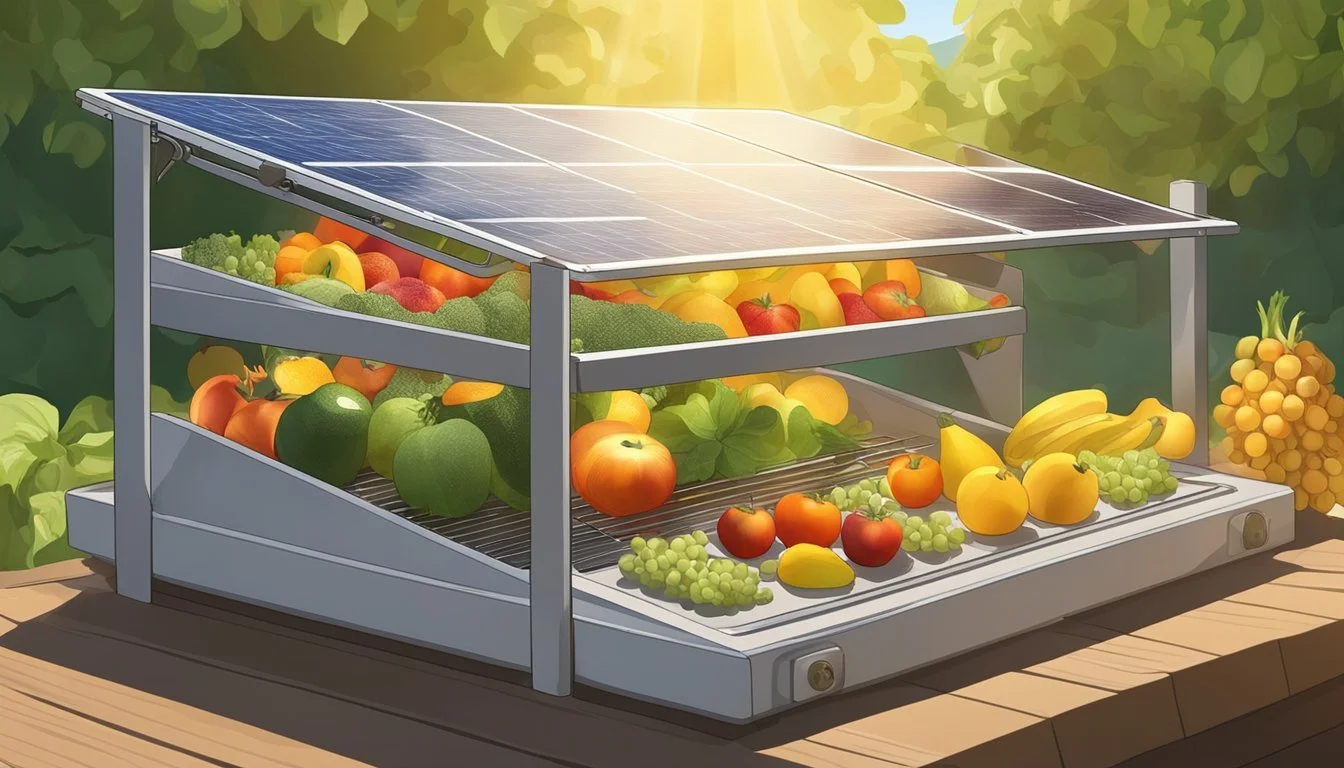

Solar dehydrators offer an eco-friendly method for preserving food using renewable energy. By harnessing the power of the sun, they provide an effective way to dry various foods, enhancing their shelf life without the use of electricity. This low-tech method of food preservation not only maintains a considerable amount of the food's nutrients but also reduces waste, offering a sustainable alternative to conventional electric dehydrators.

The process of drying food in a solar dehydrator is simple yet requires an understanding of the device's operation. The dehydrator typically consists of trays or racks for placing food in a single layer, and a system for protecting the food from insects while allowing the sun's rays to do their work. While vegetables can often dry within a single day, fruits and other juicier items might take longer, reflecting the necessity of a patient and attentive approach to solar food drying.

Throughout the drying process, users should monitor several factors, such as the positioning of the dehydrator to maximize solar gain and the need to bring the device inside during inclement weather or overnight. These practices ensure even dehydration of foods and protect them from potential spoilage, securing the benefits of the sun's energy for effective food preservation.

Fundamentals of Solar Dehydrators

Solar dehydrators utilize the sun's energy to remove moisture from food, resulting in preservation through drying. They operate on simple yet efficient design principles, using components effectively aligned to maximize the utilization of solar energy.

Design Principles

The design of a solar dehydrator focuses on trapping heat while ensuring proper air circulation to dehydrate food effectively. They generally consist of a heat-absorbing surface that captures and converts solar energy to heat, increasing the temperature inside the dehydrator. Adequate ventilation is critical, as it allows moisture-laden air to exit, ensuring a continuous flow of air that carries away the moisture from the food.

Key design principles include:

Orientation: Aligning the dehydrator towards the sun to maximize heat absorption.

Insulation: To retain the captured heat and maintain a consistent drying temperature.

Airflow: The dehydrator should have vents or openings at the bottom and top, allowing cool air to enter, heat up, and exit as warm, moist air.

Components of a Solar Dehydrator

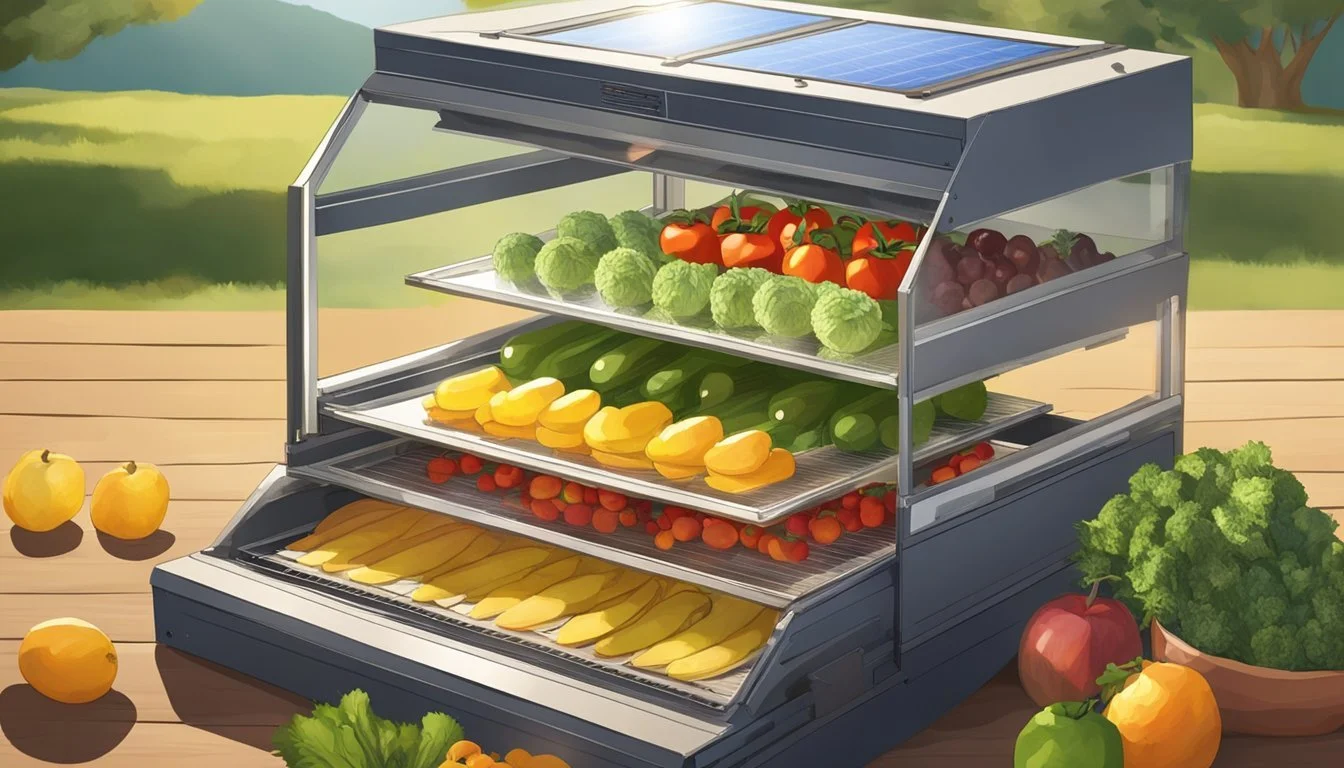

The components of a solar dehydrator work in concert to harness the sun's energy for food dehydration. The main components are:

Solar Collector: This is the part where the sun's energy is absorbed and converted to heat. It is usually a flat, dark-colored surface that can retain heat effectively.

Drying Chamber: The compartment where food is placed on trays or racks. It should be transparent or semi-transparent to allow sunlight to enter and facilitate the drying process.

Air Vents: Strategically placed to create natural convection, pulling in cool air and expelling warm, moist air.

Thermometer: Used to monitor the internal temperature to ensure foods are dried at proper temperatures.

Materials and construction must reflect the objectives of capturing heat, retaining it, and promoting air flow to achieve consistent dehydration.

Building Your Solar Dehydrator

Constructing a solar dehydrator involves careful material selection, a methodical building process, and attention to safety. The following guide will aid in setting up a functional dehydrator that effectively uses solar energy for food drying.

Choosing the Right Materials

One should select materials that are durable and conducive to capturing solar heat for their dehydrator. The main components will include:

Plywood: For the structural framework, including the collector box and drying chamber.

Glazing: Typically a transparent material like glass or clear plastic, for the cover to allow sunlight in and hold heat.

Metal or Black Paint: For the heat-absorbing surface within the collector box.

Hardware Cloth or Food-Safe Mesh: To create trays that allow for airflow and are safe for food contact.

Ensure all materials are suited for outdoor use and safe for contact with food.

Step-by-Step Construction Process

To build a solar dehydrator from scratch, one should follow these steps:

Measure and Cut Plywood: Use a circular saw to cut pieces for the dehydrator's body, including sides, back, bottom, and the angled pieces that will comprise the collector box.

Assemble Wooden Frame: Construct the frame that will hold the glazing and support the trays. Securely fasten with screws or nails.

Install Heat-Absorbing Surface: Inside the collector box, attach a metal surface painted black or another suitable material that will absorb and radiate heat.

Create Trays: Construct trays using a wooden frame and attach mesh with a staple gun, ensuring ample space for air circulation.

Attach Glazing: Secure the clear cover over the frame with screws and weather-proof seals to create a heat-retaining environment.

Install Ventilation: Build in vents to control humidity and temperature within the drying chamber.

Pay close attention to creating tight seals and maintaining structural integrity throughout the process.

Safety Considerations

When building a solar dehydrator, one must prioritize safety:

Tool Safety: Utilize all tools, like the circular saw and staple gun, following the manufacturer's safety instructions.

Material Safety: Choose non-toxic materials and ensure that any finishes, paints or sealants are food-safe and appropriate for high temperatures.

Stable Construction: Ensure that the dehydrator is stable and cannot easily tip over, particularly when loaded with produce.

Regular inspections and maintenance of the dehydrator are crucial to safe operation over time.

Preparing Food for Dehydration

Dehydration is an effective way to preserve food using the natural heat from the sun. Careful preparation of fruits, vegetables, and herbs is crucial to ensure quality outcomes.

Selecting Fruits and Vegetables

When choosing fruits and vegetables for dehydration, look for fresh, ripe, and high-quality produce. Avoid any items with signs of rot or mold. Firm fruits like apples and strawberries should be uniformly sliced to ensure even drying. With vegetables such as beans, onions, and tomatoes, ensure they are clean, ripe, and have no blemishes.

Pre-treatment of Foods

Pre-treatment can prevent certain fruits and vegetables from discoloring and can also help to preserve flavor and nutritional value. Blanching vegetables like beans for a few minutes in boiling water can halt enzyme actions which can spoil the food. For fruits, such as bananas and apples, a dip in a lemon juice solution can fend off browning. Herbs may not require pre-treatment but should be thoroughly washed.

Arranging Food on Trays

Once prepared, arrange the food in a single layer on the dehydrator trays. There should be a small space between pieces to allow air to circulate effectively:

Fruits: (e.g., sliced strawberries, apples, bananas)

Sliced Thickness: 1/4 - 1/2 inch, Arrangement: Single layer

Vegetables: (e.g., beans, diced tomatoes, chopped onions)

Cut Size: 1/2 inch pieces, Arrangement: Single layer

Ensure that each piece is arranged without overlap and the trays are secure to avoid dropping any food during the dehydration process.

Operating the Solar Dehydrator

When using a solar dehydrator, it is essential to understand the drying process, manage temperature and airflow correctly, and adjust for varying weather conditions to ensure successful dehydration of food.

Understanding the Dehydration Process

Dehydration is the method of removing moisture from food, which inhibits the growth of bacteria, yeast, and mold. Solar dehydrators use the sun's energy to produce heat, which, when combined with airflow, effectively dries food. It's critical to lay food items in a single layer on trays to allow uniform exposure to heat and air.

Temperature and Airflow Management

For optimal drying, temperatures should be high enough to evaporate moisture but not so high as to cook the food. A consistent temperature range from 95°F to 145°F is typically ideal for different foods, and a thermometer is a must for monitoring these temperatures. Proper airflow is necessary to remove the moist air away from the food, hastening the drying process.

The dehydrator must have vents or holes that allow for this airflow.

Adjusting the position of vents can help in maintaining the right temperature and humidity levels inside the dehydrator.

Monitoring and Adjusting for Weather Conditions

A solar dehydrator relies on the climate to function; thus, monitoring your local weather is crucial. On cloudy days or when there's a chance of rain, the dehydrator might not reach the desired temperatures, and food may take longer to dry.

In case of rain, protect the dehydrator with a cover to prevent moisture from seeping in.

During periods of low sunlight, extra insulation or supplementary heating may help maintain drying temperatures.

It is important to bring the dehydrator inside at night to protect from dew and to preserve the dried food’s quality. Understanding and responding to these conditions is key to the efficiency of a solar dehydrator.

Post-Dehydration Processes

After solar dehydration, proper testing for moisture content and correct storage are crucial to ensure the longevity and safety of the dried food for consumption. This section will guide you through the necessary steps to finalize the dehydration process.

Testing for Adequate Dehydration

One should test the dried food items to ensure they have reached an ideal moisture content level. Fruits have adequately dehydrated when they are pliable but not sticky or moist; vegetables should be brittle. If a piece of food feels moist, it needs more drying time. Testing must be done when items cool to avoid false results.

Fruits: Squeeze a piece to check for stickiness or moisture.

Vegetables: Bend or break a piece to ensure brittleness.

Storing Dehydrated Foods

Once dehydration is confirmed, they must move the food to a cool and dark storage location. Dehydrated goods should be stored in airtight containers or vacuum-sealed bags to maintain their shelf-stable quality, as exposure to air can reintroduce moisture and lead to spoilage.

Steps for Proper Storage:

Place dried goods into airtight containers.

Label the containers with the date of dehydration.

Store in a dark, cool, and dry place.

Prolonging Shelf-Life

To prolong the shelf-life of dehydrated foods, one can take additional precautions. It's advisable to check periodically for signs of moisture or spoilage and consume within a year for the best quality.

Inspect Regularly: Every few months, inspect your stored foods.

Oxygen Absorbers: Use these in packaging to minimize oxidation.

Proper Rotation: Use the oldest items first and replace them with newer dried goods.

By ensuring that the dehydrated goods have limited exposure to moisture, light, and air, their shelf-life can be significantly extended, preserving their nutritional value and taste until they are ready for consumption.

Comparing Solar and Electric Dehydrators

When selecting a dehydrator, one must consider various factors such as cost-efficiency, nutrient retention, and environmental impact. Electric and solar food dehydrators differ significantly in these areas, guiding the choice for consumers seeking a sustainable, cost-effective food preservation method.

Cost and Efficiency Analysis

Solar food dehydrators harness the sun's energy, which makes them incredibly inexpensive to operate. The lack of electricity usage translates to no ongoing costs post-purchase, except for the occasional maintenance. On the other hand, electric food dehydrators depend on electricity to function, which can lead to higher operational costs over time.

Solar Dehydrator:

Cost: Very low operational cost; possible materials cost if DIY

Efficiency: Weather-dependent, but low energy use

Electric Dehydrator:

Cost: Higher purchase price; ongoing energy costs

Efficiency: High and consistent regardless of weather

Impact on Nutrient Retention

Both solar and electric dehydrators can retain a high level of nutrients in dried foods when used properly. Electric dehydrators offer more control over the temperature, which can be critical for preserving sensitive vitamins and minerals. Solar dehydrators may have less precise temperature control, but they can still effectively preserve nutrients if managed carefully.

Environmental Considerations

From an environmental standpoint, solar dehydrators are more environmentally friendly as they do not consume fossil fuels and reduce the carbon footprint associated with food preservation. Meanwhile, electric dehydrators, unless powered by renewable energy sources, use electricity that may come from non-renewable resources, contributing to environmental concerns such as greenhouse gas emissions.

Maintenance and Troubleshooting

Maintaining a solar dehydrator is critical for ensuring that it functions optimally. Regular cleaning, prompt resolution of issues, and measures to protect the dehydrator help maintain its durability and longevity.

Cleaning and Upkeep

Cleaning the solar dehydrator is essential to prevent the growth of molds and bacteria, which can spoil food and pose health risks. Users should:

Remove any food particles after each use.

Wipe the interior surfaces with a damp cloth to remove any residues.

Occasionally clean the drying racks in soapy water, rinsing and drying them thoroughly before reuse.

Check for and remove any insects or pests that may have entered the dehydrator.

Addressing Common Issues

Customers may encounter several operational issues. Here are ways to address them effectively:

Uneven Drying: Ensure racks are not overcrowded and that there's adequate airflow around each item.

Low Heat: Verify that the solar dehydrator is positioned to maximize sun exposure.

Moisture Buildup: Check seals to ensure the dehydrator is properly enclosed and that any venting systems are clear and functional.

Ensuring Durability and Longevity

To guarantee the durability and longevity of a solar dehydrator, users must take proactive steps:

Protect the dehydrator from harsh weather conditions by storing it indoors when not in use.

Periodically inspect the structure for any signs of wear or damage and make repairs as needed.

Invest in quality materials for any replacement parts, such as non-corrosive metals or UV-resistant plastics.

Advanced Techniques and Tips

The following section delves deeper into optimizing the use of a solar dehydrator, preserving a variety of foods, and exploring innovative applications for solar dehydrators. Through the proper adjustment of screens and vents, users can fine-tune dehydration processes to ensure high-quality dried products.

Enhancing Dehydrator Performance

Ventilation: To increase dehydration efficiency, managing airflow is crucial. Users should adjust vents to maintain an internal temperature between 95°F to 145°F. Properly sized vents can improve air circulation, preventing moisture buildup and ensuring even drying.

Insulation: Adding insulation to a solar dehydrator can significantly boost its ability to retain heat. Materials like foam board or dual-pane windows help hold in solar power, leading to faster and more consistent drying results, particularly for foods requiring lower humidity.

Drying Specialty Foods

Dried Fruits: When drying fruits, uniform slicing is key; each piece should be cut to a similar thickness to achieve even drying and optimal taste. Specialty fruits, like figs or mangoes, may require pre-treatment with citrus juice or syrup to enhance flavor and color retention.

Jerky: For making jerky, the meat should be sliced no thicker than 1/4 inch and marinated for flavor enhancement. The drying process for jerky is more exacting, requiring close attention to avoid under or over-drying, which can impact both taste and safety.

Corn: When drying corn, husk and blanch the ears before slicing off the kernels. Spread them on the screen in a single layer, and they should dry within a day in optimal sunlight, preserving their high fiber content effectively.

Creative Uses of Solar Dehydrators

Herb Drying: Users can harness a solar dehydrator for culinary and medicinal herbs, which can be dried whole or chopped. Small mesh screens can trap fine leaves and prevent loss while allowing for full air circulation.

Mushroom Drying: Solar dryers excel at drying mushrooms thanks to their low-temperature requirements. Users should clean mushrooms gently and slice them before placing them on the drying screen. Drying times will vary depending on the thickness and type of mushroom.

Seed Saving: A less common but valuable use of solar dehydrators is for seed saving. Dryers can facilitate the removal of moisture from seeds, which is paramount for long-term storage and viable planting.

In every case, users should ensure that their dehydration trays are fitted with a proper mesh or screen to prevent insects from contaminating the food. The creative use of a solar dryer not only enhances the drying method but also contributes to a sustainable lifestyle by leveraging renewable solar power.

Legal and Safety Regulations

When harnessing solar energy to dehydrate food, adhering to legal and safety regulations is critical. These requirements ensure that both the construction of the dehydrator and the resulting dried products meet health and safety standards, reducing risks associated with consumption and the potential growth of microorganisms.

Compliance with Standards

Safety Standards: Manufacturers or DIY builders should ensure that the solar dehydrator meets the applicable local building codes and safety standards. This could involve materials used, structural integrity, and stability to prevent accidents or collapses.

Regulations: They should also verify that any electrical components, if used to supplement solar heating, comply with electrical safety standards. Clear documentation and labeling might be required, particularly if the dehydrator is intended for commercial use.

Handling and Consumption Safety

Prevention of Microorganism Growth: Adequate drying is crucial in preventing the growth of harmful microorganisms. It is important to achieve and maintain the necessary internal temperatures, which should comply with food safety guidelines for drying different types of produce.

Safe Consumption: To ensure safe consumption, the dehydration process should result in moisture levels that inhibit the growth of bacteria, molds, and yeasts. Individuals should be informed about proper handling, storage after drying, and preparation before consumption to maintain food safety.

Handling: Users must ensure appropriate cleaning and maintenance routines for the dehydrator's surfaces that come into contact with food.

Storage: Dried foods should be stored in airtight containers, and users should be aware of the shelf life of various dehydrated products to prevent spoilage.

These sections highlight the essential legalities and safety precautions that need to be observed when using a solar dehydrator.

Conclusion

A solar food dryer is an indispensable tool for those looking to effectively preserve their harvest without reliance on electrical energy. By harnessing the sun's rays, individuals can dehydrate crops with minimal cost and environmental impact, ultimately gaining food security and reducing waste.

Solar dehydrators utilize a simple, yet ingenious design that capitalizes on the sun's energy, transforming it into heat for the drying process. They work most efficiently in climates with abundant sunshine, making them suitable for a wide array of geographical areas.

Key considerations when using a solar dehydrator include:

Placement: Ensure the dehydrator faces the sun for maximum exposure.

Temperature Monitoring: Keep internal temperatures between 120-140 degrees to avoid cooking the food.

Weather Awareness: Protect the dehydrator from nightly moisture and rain.

Originating from designs possibly first conceptualized at institutions such as Purdue University, these devices reflect a marriage between traditional preservation methods and modern innovation. Items like the solar oven share a common renewable principle, highlighting a broad commitment to sustainable practices.

In utilizing a solar food dryer, one not only invests in the sustainability of their food preparation practices but also contributes to the preservation of the environment. This confidence-inspiring device assures the user of their ability to secure nutrition from their harvest, using a method that is as friendly to the earth as it is effective.